new technology

- Nanomaterial polymer dispersion technology

- High heat dissipating composite material technology

- Graphene Manufacturing Technology

CNT conductive composite material

Material that maintains and enhances the existing physical properties of polymer material; and material that transmits conductivity at low amounts by distributing highly conductive carbon nanomaterial on polymer material

Surface Resistance : 103 ~ 107 Ω/sq

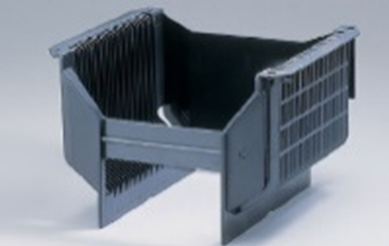

ESD Clean room Chair

Conductive Fiber

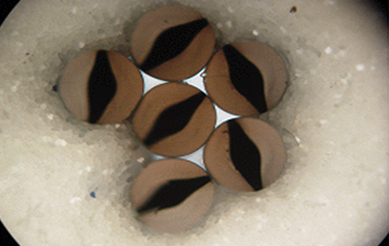

Wafer Tray

| Grade | C130G | C1370 | CNP100-ST | C1355 | C800A | C1300 |

|---|---|---|---|---|---|---|

| Base Polymer | PA6 | TPU | PA6 | TPE | ABS | ETFE |

| Conductivity | 10 5~106 | 106~107 | 105~106 | 106~107 | 106~108 | 104~106 |

| GF Contents | 30% | |||||

| Application | mobile item | mobile item | caster | mobile item | electric item | mobile item |